The manufacturing industry has always been a cornerstone of economic growth, driving innovation and delivering products that shape our everyday lives. However, traditional manufacturing methods often come with challenges, such as high costs, material waste, and lengthy production cycles. commercial 3d printing services are addressing these issues, transforming how businesses approach production, and unlocking a new era of efficiency and creativity.

What is Commercial 3D Printing?

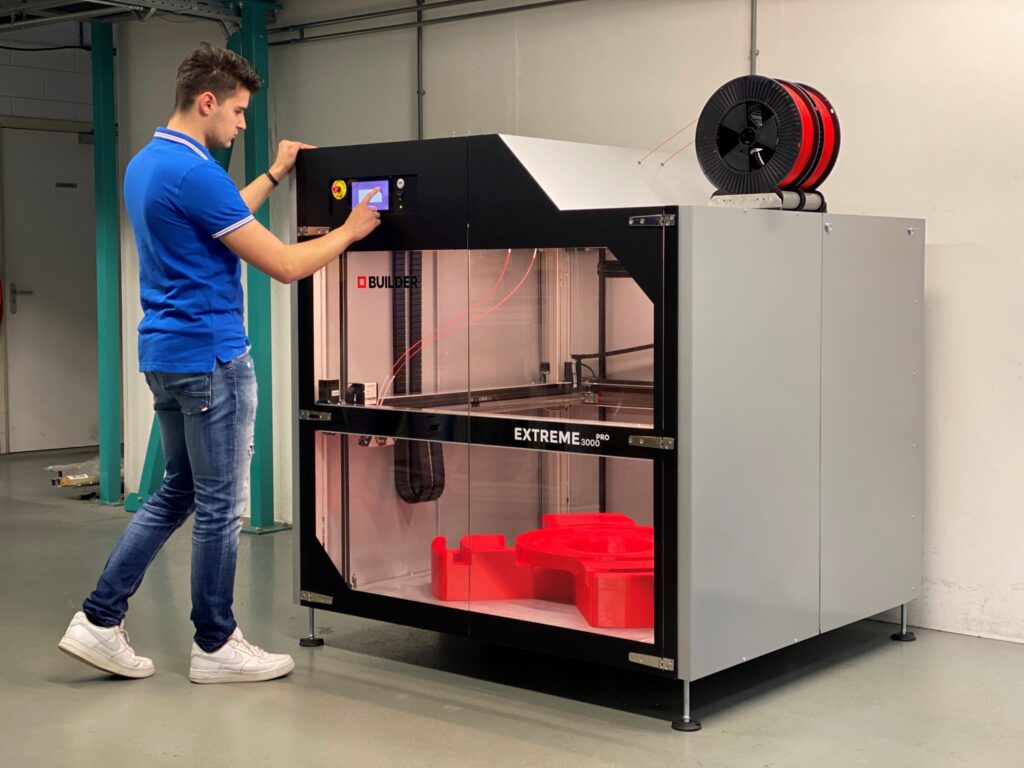

Commercial 3D printing, also known as additive manufacturing, involves creating three-dimensional objects layer by layer using digital design files. Unlike subtractive methods, which cut away material from a larger block, 3D printing builds objects from the ground up, minimizing waste and offering unmatched precision.

These services cater to industries ranging from aerospace to consumer goods, offering solutions for prototyping, small-batch production, and custom parts manufacturing.

Key Ways 3D Printing is Revolutionizing Manufacturing

- Enhanced Prototyping and Product Development

Traditional prototyping methods can be time-consuming and costly, especially for intricate designs. 3D printing enables manufacturers to create high-fidelity prototypes quickly and affordably, allowing for rapid testing and iteration. This accelerates the product development cycle, helping businesses bring products to market faster. - Cost Reduction

- Tool-Free Manufacturing: 3D printing eliminates the need for expensive molds and tools, significantly reducing upfront costs.

- Minimized Material Waste: Additive manufacturing uses only the material required to build the part, cutting down on waste and material expenses.

- Complex Design Capabilities

Traditional methods often struggle to produce intricate designs or require multiple components to be assembled. With 3D printing, manufacturers can create complex geometries, including lightweight lattice structures and integrated parts, all in a single build. - Customization and Personalization

3D printing allows manufacturers to produce customized products without increasing production costs. This capability is particularly valuable in industries like healthcare, where patient-specific implants and devices are becoming the norm. - On-Demand Manufacturing

With 3D printing, manufacturers can produce parts on demand rather than maintaining large inventories. This reduces storage costs, minimizes overproduction, and ensures quick access to replacement parts. - Sustainability and Eco-Friendliness

- Reduced Carbon Footprint: Additive manufacturing requires less energy and raw material compared to traditional methods.

- Recyclable Materials: Many 3D printing processes use recyclable or biodegradable materials, further reducing environmental impact.

Industries Leading the Transformation

- Aerospace and Defense

The aerospace industry benefits from 3D printing’s ability to create lightweight yet durable components, reducing fuel consumption and emissions. Complex parts like turbine blades and custom tools are now commonly 3D-printed. - Automotive

Automotive manufacturers are using 3D printing for prototyping, custom parts, and even final production. The technology enables the creation of lighter components, improving vehicle efficiency and performance. - Healthcare

From prosthetics to surgical tools, 3D printing is revolutionizing the healthcare industry. Patient-specific implants and devices enhance treatment outcomes and improve quality of life. - Consumer Goods

Brands in the consumer goods sector leverage 3D printing to create unique, customizable products such as eyewear, footwear, and home decor items. - Industrial Equipment

Manufacturers of industrial machinery and equipment use 3D printing to produce complex parts that are difficult or impossible to make using traditional methods.

Challenges and Opportunities

While 3D printing offers immense potential, it’s not without challenges. The initial investment in high-quality printers and materials can be significant, and not all materials are suitable for additive manufacturing. However, advancements in technology are continually improving affordability and material options, making it more accessible to businesses of all sizes.

Opportunities for further growth include:

- Integration with AI and IoT: Smart manufacturing systems can enhance 3D printing workflows, improving precision and efficiency.

- Expansion of Material Choices: Emerging materials like composites and bio-compatible polymers will open new possibilities for additive manufacturing.

- Mass Customization: The ability to produce personalized products at scale will revolutionize industries such as retail and healthcare.

The Future of Manufacturing with 3D Printing

As technology advances, commercial 3D printing services will continue to redefine manufacturing processes. From enabling localized production to supporting innovative designs, the future of manufacturing lies in embracing this transformative technology.

By adopting 3D printing, businesses can:

- Stay competitive in a rapidly evolving market.

- Achieve greater efficiency and sustainability.

- Innovate faster and cater to dynamic customer demands.

Conclusion

Commercial 3D printing services are not just transforming manufacturing—they’re reshaping the possibilities of what businesses can achieve. By combining precision, efficiency, and flexibility, this technology is driving a revolution that will define the next era of production. Embracing 3D printing today means investing in the future of manufacturing.